3 Innovative Heat Insulation Solutions for HNB Vape Devices

Introduction

As the vape and e-cigarette industry evolves, Heat-Not-Burn (HNB) devices have gained popularity for offering a smoother alternative to traditional smoking. However, one critical challenge in HNB device design is heat management—since the heating chamber reaches temperatures of around 300°C, effective thermal insulation is essential to prevent burns and improve user safety.

This article explores three advanced heat insulation solutions for HNB devices:

- LCP (Liquid Crystal Polymer) Insulation Sleeve

- PI (Polyimide) Foam Insulation Tube

- 3D-Printed Porous Ceramic Tube

Each solution offers unique benefits in terms of thermal resistance, cost-efficiency, and manufacturability, making them ideal for modern vapor products.

1. LCP Insulation Sleeve: High-Performance Thermal Barrier

Structure & Design

- Dual-layer construction: Inner and outer sleeves with heat-resistant insulation material (e.g., aerogel, foam resin, or thermal cotton) in between.

- Optimized contact reduction: Minimizes direct heat transfer from the heating element.

Key Advantages

✔ Ultra-low thermal conductivity – Better than traditional PEEK resin.

✔ Flame-retardant (UL94 V-0 rated) – Ensures fire safety.

✔ High heat resistance – Withstands up to 340°C.

✔ Thin-walled design (0.2mm minimum) – Saves space without compromising insulation.

✔ Easy to manufacture – Excellent flowability for injection molding.

Applications in HNB Vape Devices

- Ideal for compact pod-style HNB vaporizers.

- Commonly used in refillable and disposable e-cigarette designs.

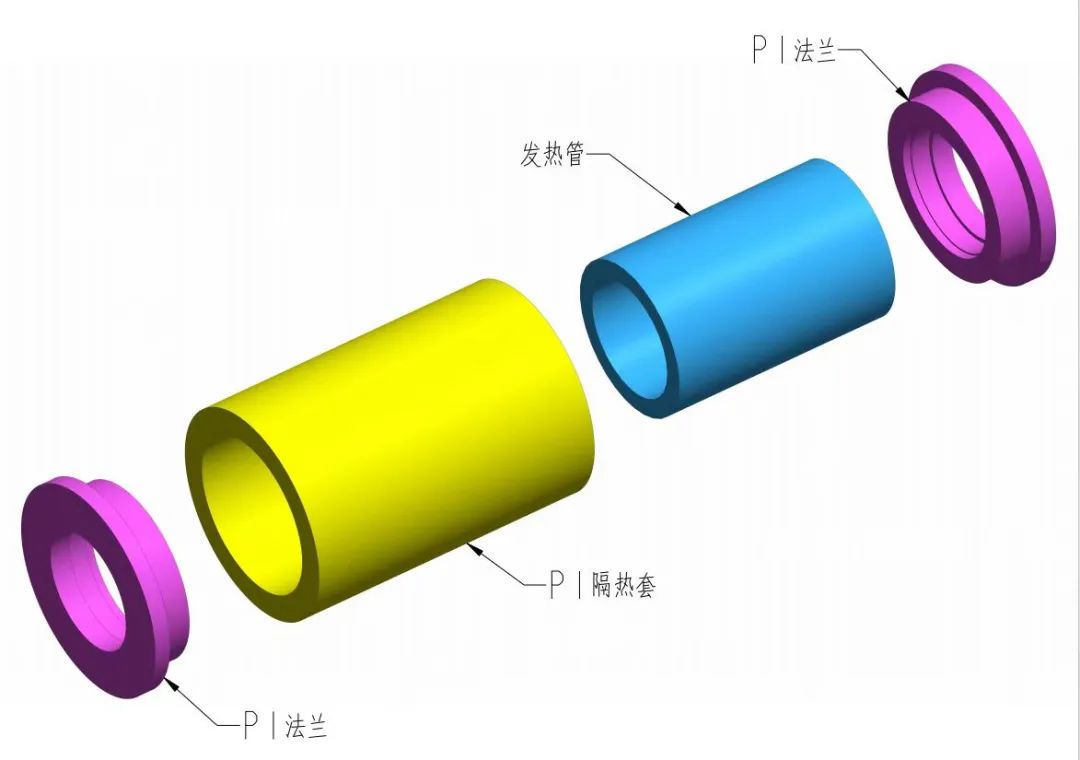

2. PI Foam Insulation Tube: Lightweight & High-Temperature Resistant

Structure & Design

- Made from polyimide (PI) foam, processed via supercritical technology to form PI aerogel.

- Single-piece tube design – Ensures uniform insulation.

Key Advantages

✔ Extremely low thermal conductivity – Enhanced insulation performance.

✔ Wide temperature range (-260°C to 300°C long-term, 350°C+ short-term).

✔ No toxic fumes – Safe for consumer use.

✔ Modular installation – Simplifies assembly in e-cigarette manufacturing.

Applications in HNB Vape Devices

- Best for premium HNB devices requiring consistent heat dissipation.

- Used in high-end vapor products where safety and durability are critical.

3. 3D-Printed Porous Ceramic Tube: Cost-Effective & Scalable

Structure & Design

- Gradient porous structure: Combines ordered macro-pores + disordered micro-pores for optimal insulation.

- 3D-printed manufacturing – Allows rapid, large-scale production.

Key Advantages

✔ Superior heat resistance – Better than traditional stainless steel vacuum tubes.

✔ 30% cost reduction – More affordable than metal alternatives.

✔ High-speed production – 2,000+ units per hour possible.

✔ Customizable porosity – Adjustable for different vape device requirements.

Applications in HNB Vape Devices

- Perfect for mass-market disposable e-cigarettes.

- Used in fruit-flavored vape products where cost efficiency matters.

Comparison of the Three Solutions

| Feature | LCP Insulation Sleeve | PI Foam Tube | 3D-Printed Ceramic Tube |

|---|---|---|---|

| Max Temp Resistance | 340°C | 350°C+ | 300°C+ |

| Thermal Conductivity | Very Low | Extremely Low | Low |

| Cost Efficiency | Moderate | High | Best (30% cheaper) |

| Manufacturing Speed | Fast (Injection Molding) | Moderate | Very Fast (3D Printing) |

| Best For | Mid-to-high-end devices | Premium devices | Budget & mass-market vapes |

Future Trends in HNB Insulation Technology

- Hybrid Materials – Combining LCP, PI, and ceramic for enhanced performance.

- AI-Optimized 3D Printing – Further reducing costs while improving insulation.

- Eco-Friendly Insulation – Biodegradable materials for sustainable vapor products.

Conclusion: Choosing the Right Insulation for Your HNB Vape Device

Selecting the best heat insulation solution depends on:

- Budget (3D-printed ceramic is most cost-effective).

- Performance needs (PI foam offers the best insulation).

- Production scale (LCP suits high-precision manufacturing).

As the e-cigarette and fruit-flavored vape markets expand, innovative thermal management solutions will play a crucial role in product safety and user experience. Manufacturers should evaluate these options to stay competitive in the fast-growing vape industry.

Discover more from Ameca-mall

Subscribe to get the latest posts sent to your email.