Beyond the Coil: Exploring the Cutting-Edge Tech Powering Your Vape’s Flavor & Cloud

The global vaping landscape is no longer just about nicotine delivery; it’s an evolving symphony of flavor, satisfaction, and technological innovation. While the sight of vapor is familiar, the intricate physics orchestrating the transformation of delicate e-liquid into the satisfying aerosol we inhale is undergoing a quiet revolution. Moving far beyond the simple coil-and-wick setup, a diverse array of vape vapor technologies are emerging, promising enhanced flavor fidelity, smoother draws, and greater consistency. Understanding these vape atomization methods – heating, ultrasonic, centrifugal, compressed, and surface acoustic wave – is key to appreciating the future of E-cigarette experiences, especially for discerning fans of complex Fruit Flavored Vape profiles.

The Unseen Alchemy: What is Vaporization?

At its core, vaporization is a physical process where a liquid transforms into a suspension of fine droplets or gas (aerosol), visible as vape vapor. This isn’t combustion; it’s a phase change achieved by imparting energy to overcome the liquid’s surface tension and cohesive forces. The method of energy delivery defines the technology and profoundly impacts the user experience – the temperature reached, the aerosol particle size, the flavor preservation, and the overall sensation.

1. Thermal Dominance: The Reign of Heating Atomization

Heating atomization remains the undisputed mainstream technology in E-cigarette devices. Its principle is straightforward: apply heat to raise the e-liquid’s temperature past its boiling point, creating vapor that rapidly condenses into aerosol droplets upon contact with cooler air.

- The Workhorse: Resistive Heating: The vast majority of devices utilize a simple, effective, and cost-efficient method: resistive heating. An electric current passes through a coil (usually metal wire like Kanthal, Nichrome, or stainless steel), generating heat via resistance. This heat transfers directly (conduction) or via a saturated wick (often cotton) to the e-liquid, causing vaporization. Its advantages – high efficiency, relatively low cost, and design simplicity – cement its dominance.

- Beyond the Coil: Diverse Heating Pathways: The science of heat transfer (conduction, convection, radiation) opens doors to alternative thermal methods:

- Electromagnetic Induction: A rapidly alternating magnetic field induces electrical currents in a conductive material (like a metal plate or mesh), generating heat directly within the material contacting the liquid. This allows for faster, potentially more even heating without a traditional coil touching the wick.

- Microwave Heating: Microwaves excite water and glycol molecules within the e-liquid itself, generating internal heat. While technically feasible, precise control and safety considerations make it less common currently.

- Infrared (IR) Radiation: IR emitters transfer heat energy via radiation directly to the liquid surface or a heating element. This offers non-contact heating possibilities.

- Advanced Concepts: Other explored avenues include chemical reaction heating (exothermic reactions releasing heat), phase-change heat pipes (using vaporization/condensation cycles to efficiently move heat), laser heating (highly precise but complex), and radiofrequency (RF) heating (similar to microwave but different frequency).

Why Heating Still Rules (and its Challenges): Its maturity, efficiency, and cost-effectiveness are unmatched. However, inherent challenges persist: the risk of overheating leading to “dry hits” and burnt flavor (especially detrimental to subtle Fruit Flavored Vape notes), potential thermal degradation of delicate flavor compounds at high temperatures, and the generation of compounds like formaldehyde under certain extreme conditions (though well-designed devices mitigate this).

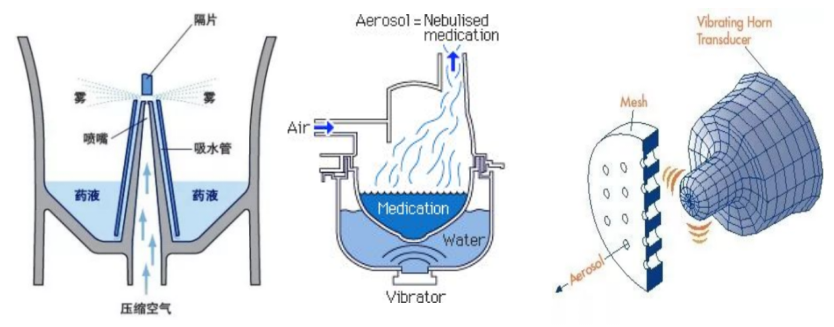

2. The Gentle Touch: Ultrasonic Atomization Enters the Vape Arena

Familiar in medical nebulizers, ultrasonic atomization takes a radically different approach. Instead of heat, it uses high-frequency vibrations (typically generated by piezoelectric ceramics) to literally shatter liquid into a fine mist. Imagine tiny, powerful sound waves agitating the liquid surface until microscopic droplets are ejected.

- How it Works for Vaping: An ultrasonic atomizer features a vibrating element (often a piezoelectric disc or mesh). E-liquid is fed onto this vibrating surface. The intense high-frequency vibrations create capillary waves on the liquid film. When the amplitude is sufficient, these waves break apart, releasing ultra-fine droplets directly as aerosol – no boiling required. Temperature rises minimally, often staying near ambient.

- Tackling the Pain Points: This “cool vaporization” directly addresses key drawbacks of heating methods:

- No Burnt Taste: Eliminates the risk of dry hits and scorching, preserving the true flavor profile.

- Enhanced Flavor Fidelity: Lower temperatures prevent thermal decomposition of complex flavor molecules, crucial for authentic Fruit Flavored Vape experiences.

- Consistency: Potentially offers more stable aerosol production.

- Innovation in Design: Vaping applications require overcoming challenges like liquid feed rate control and sufficient vapor production. Solutions involve sophisticated wicking structures (e.g., specialized porous ceramic plates), optimized reservoir designs, precise airflow management, and even hybrid systems:

- Dual Ultrasonic: Using two transducers for increased output.

- Ultrasonic + Heat: Combining ultrasonic mist generation with mild, controlled heating just to warm the aerosol for a more traditional feel, without risking combustion.

3. Spinning Perfection: The Promise of Centrifugal Atomization

Centrifugal atomization leverages physics in a visually compelling way. Think of a high-speed spinner flinging liquid off its edges.

- The Magnetic Spin: At the heart is a low-power magnetic levitation system spinning a rotor at extremely high RPMs. E-liquid is fed onto the center of this spinning disc or cone. Centrifugal force instantly spreads the liquid into an ultra-thin film moving rapidly outward. As the liquid reaches the edge, it’s flung off, breaking into a fine aerosol. Simultaneously, the spinning creates airflow that propels the vapor out.

- Benefits Over Heat: This method fundamentally bypasses the core issues of resistive heating:

- Zero Dry Hits/Scorching: No heating element exists to burn residue.

- Enhanced Safety: Avoids the high temperatures that can potentially generate unwanted compounds.

- Preserved Flavor: Cool operation protects volatile flavorings from thermal breakdown.

- Smooth Experience: Typically produces a very cool, smooth vapor.

4. Precision Spray: Compressed Atomization Mimicking Tradition

Compressed atomization draws inspiration from inkjet printing or medical inhalers. It relies on pressure to force liquid through microscopic nozzles, creating a fine spray.

- Pressure-Driven Precision: A pump or pressurized reservoir creates the force. E-liquid is driven through an array of extremely small, precisely engineered orifices. As the liquid jet exits the nozzle, it naturally breaks up into droplets due to instabilities. Sophisticated designs using piezoelectric actuators can create precise droplets on demand.

- Targeted Advantages: This approach offers unique control:

- Targeted Sensation: Can be engineered to simulate the specific throat hit and aerosol density of traditional cigarettes.

- Quantitative Control: Offers the potential for extremely precise dosing of nicotine or flavor.

- Aerosol Uniformity: Capable of producing highly monodisperse (same size) droplets for consistent sensory impact.

- Reduced Waste: Potentially minimizes residual liquid.

5. The Surface Wave Revolution: SAW Atomization

Surface Acoustic Wave (SAW) atomization represents perhaps the most futuristic approach currently explored for vaping. It manipulates sound waves on a chip’s surface.

- Waves on a Chip: A piezoelectric substrate (like quartz or lithium niobate) has interdigital transducers (IDTs) patterned onto it. Applying an alternating electrical signal to the IDTs generates a Surface Acoustic Wave – an acoustic ripple traveling along the chip’s surface.

- Atomization at the Microscale: A tiny droplet of e-liquid is placed directly in the path of this traveling acoustic wave. The intense acoustic energy disrupts the droplet’s surface tension, causing it to “atomize” directly into a fine mist of sub-micron aerosol particles. The frequency and power of the SAW directly control the atomization rate and particle size.

- Unmatched Potential Control: SAW technology boasts significant theoretical advantages:

- Extreme Precision: Allows for near-perfect quantitative control over the exact amount of liquid atomized per puff.

- Sensory Consistency: Enables unparalleled consistency in aerosol density and particle size, puff after puff.

- Compact Simplicity: The core atomizer can be incredibly small and integrated onto a microchip.

- Instant On/Off: Atomization starts and stops virtually instantaneously with the electrical signal.

The Future of Flavor and Experience

The evolution of vape vapor technology is accelerating beyond the simple heated coil. While heating atomization remains dominant due to its maturity and cost, its limitations in flavor preservation and potential for undesirable byproducts are driving innovation.

- Ultrasonic and Centrifugal technologies offer compelling “cool vapor” alternatives, promising purer flavor experiences, especially vital for the nuanced profiles of popular Fruit Flavored Vape liquids, and enhanced safety profiles.

- Compressed methods provide a pathway to ultra-precise aerosol delivery and potentially more authentic traditional cigarette sensations.

- SAW technology, though likely further from mass-market adoption, represents a potential paradigm shift towards digital precision control over the vaping experience.

Implications for Vapers and the Industry:

- Enhanced Flavor: Cooler vaporization methods mean more authentic, complex, and enjoyable flavor profiles.

- Smoother & Safer Experience: Reduction or elimination of dry hits and potentially harmful thermal degradation products.

- Greater Consistency: Technologies like SAW and compressed aim for near-perfect puff-to-puff replication.

- Product Diversification: Expect to see more devices boasting “ultrasonic mist,” “cool spin tech,” or “precision spray” as key selling points.

- Regulatory Considerations: As new technologies emerge, demonstrating reduced risk profiles compared to combustion or even high-temperature heating could be significant.

Conclusion: An Inhale of Innovation

The journey from e-liquid bottle to satisfying cloud of vape vapor is becoming increasingly sophisticated. The move beyond basic heating opens a new chapter for the E-cigarette industry, one focused on maximizing flavor integrity, ensuring consumer safety, and delivering unparalleled consistency. Whether it’s the gentle vibrations of ultrasonic, the high-speed spin of centrifugal, the precise spray of compressed systems, or the micro-scale control of SAW, the future of vaping promises a cooler, cleaner, and more flavorful experience. For consumers, particularly those who savor the intricate notes of Fruit Flavored Vape, and for forward-thinking manufacturers and sellers, understanding and embracing these diverse atomization technologies is key to navigating the next wave of innovation in the dynamic world of vaping. The quest for the perfect puff continues, driven by physics and engineering ingenuity.

Discover more from Ameca-mall

Subscribe to get the latest posts sent to your email.